Automation and Internet cloud computing are evolving and merging into a space allowing for artificial intelligence or A.I. programming to facilitate improvements in productivity and efficiency with many economic benefits, along with Internet cloud computing and other advancements with the Internet, we are now in the middle of the next industrial revolution, mining and turning data into information. This period of evolution is called Industry 4.0 or the Fourth Industrial Revolution, which includes industrial Internet of Things IoT and digital transformation mechanisms that facilitate this evolved fourth-generation period of automation.

In this post, we will talk about what is the industrial Internet of Things or IoT.

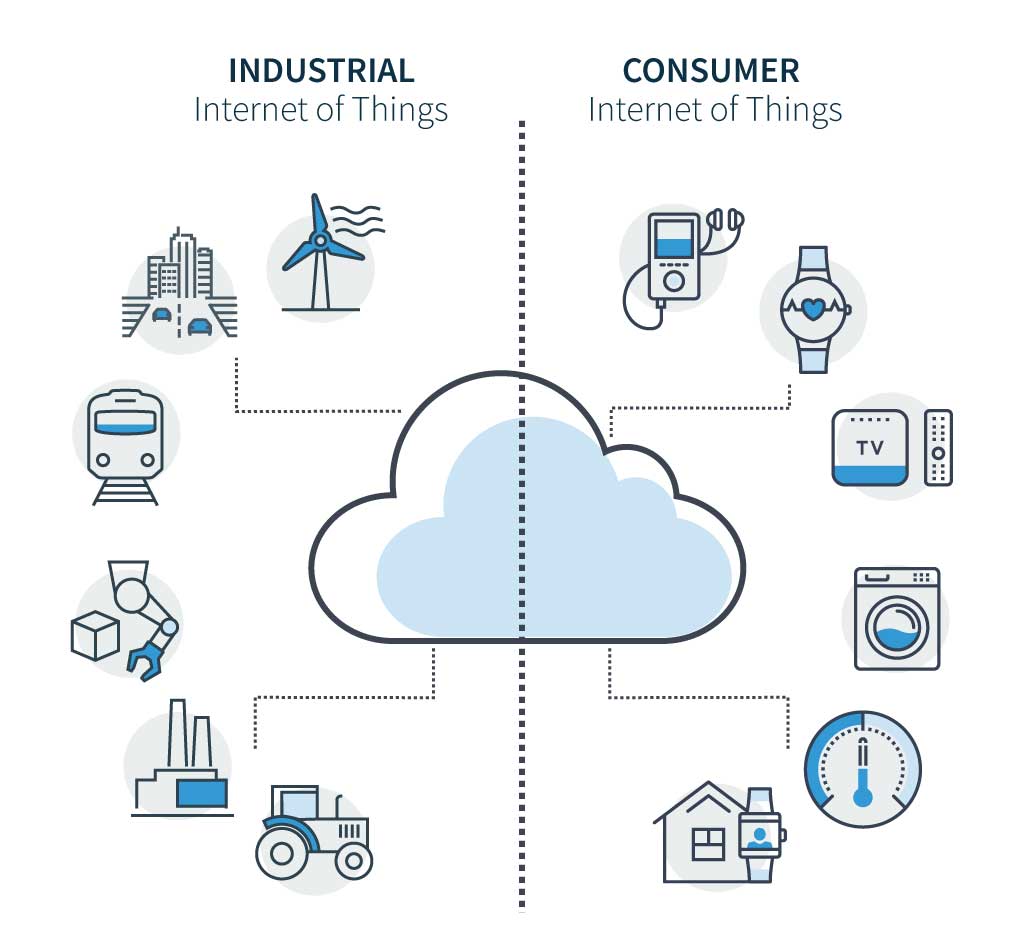

While the industrial Internet of Things does fall under the Internet of Things or IoT area of influence, the key difference is Iot concentrates on the connections of machines and devices and industries like manufacturing, health care and logistics.

IoT is commonly used to define consumer based devices like smartwatch and a wide range of smart home devices. For example, refrigerators, video doorbells, lighting thermostats and alarm systems. Iot is about getting information that every single consumer needs in their hands when they want it, and digital transformation is the digitization of a business and how we must move to a unified, organized data space using the International Society of Automation standard for developing an automated interface between enterprise and control systems, or ISA 95.

ISA95 essentially provides a hierarchical model for the enterprise- site- area and line. Each level of this architecture uses a specific software system to gather data for that part of the organization needs in which creates a problem for communication between these disparate applications. With most organizations, the data is not real time and lacks efficiency, inhibiting key stakeholders to make informed decisions, IoT is about making decisions from information received real time and not from a report created from yesterday’s data!

The industrial Internet of Things is all about interconnected instruments, sensors and many other devices that are networked together and communicating with computer driven industrial applications for many manufacturing and energy management areas of business. IoT is an evolution of a control system that allows for a significant improvement in automation by using cloud computing to enhance and optimize process controls. Industrial IoT depends on many technologies, but the key technologies primarily consist of artificial intelligence, cybersecurity, cloud computing, edge computing and data mining

Artificial intelligence or A.I. and machine learning are part of computer science, A.I. is where intelligent machines are developed and respond like humans. Cybersecurity technology becomes an important basic platform for IoT, enabling disconnected machines to physically connect and communicate in a secure method. Cloud computing is basically using IT services and the files to be uploaded and downloaded from Internet-based servers as opposed to using local extranet connected servers

Edge Computing is a distributed computing model, bringing data storage closer to the location where it is needed and optimizes sensors, industrial computers and devices that are part of the Iot system for publishing and consuming data for faster processing. Data mining and analytics are about collating and examining large amounts of data stored from various parts of the enterprise.

What are the Business Benefit of Data Mining?

BUT why should we go through this somewhat major transformation and what are the benefits? Companies want to be more competitive, increase efficiency with Just-In-Time manufacturing and meeting higher customer demand with better inventory control. We can do all of this with the creation of the organization’s overall automation, – digital twin. A digital twin is a virtual representation, referring to a digital replication of the actual company’s physical assets, processes in place, automation systems and devices. The twin uses real-time data to enable learning and reasoning for improved decision making. The digital twin allows experimentation with new information that is generated by cloud-based A.I. functions without having to shut down production or be concerned with personal safety because testing is performed in a virtual space.

Also, the digital twin could be used as a training ground for new employees without impacting the live system. And when comparing IoT and IIoT failures, IIot creates much higher risks than IoT. Life-threatening situations or major financial losses could happen from an actual system failure or downtime.

While we may benefit from a long list of benefits through the IoT transformation, there are some concerns and risks we should be aware of. Some of the potential risks of adopting IoT are expensive, the cost of data integration, lack of experience and difficulty of implementation, and the devastating cyber threats

Data integration is one of the biggest obstacles to IIoT implementation. You could be looking at building a system with thousands of existing connected sensors and devices, adding new equipment and software systems and interfacing legacy equipment to communicate using standard IoT protocols. There is a high cost of integration, preparing for IIoT, requiring new software, hardware and equipment. You will need to consider the costs of associated training, your existing workforce and hiring new staff and the time needed to get workers productive.

And the lack of expertise with integrating IIoT, requiring automation companies to fully experienced within organizations layers of systems, starting with the plant floor transmitters process, PLC operation, HMI and Scada reporting based on database, administration manufacturing execution systems or MES for Warehouse Control and Enterprise Resource Planning, or ERP or accounting systems.

Now integrators are required to have expertise in machine learning, data science and real-time analytics.

In the long term, IIot could more than pay for itself, but many organizations are still justifiably concerned about investing so much in IIot. On the bright side, the benefits of IIot in manufacturing, pharmaceuticals, agriculture, mining, oil and gas and retail are gaining ground, and many companies are embracing this new paradigm for solutions and optimizing operations and personnel productivity. Many manufacturers have already achieved process performance and have reductions in downtime. And while manufacturing is certainly leading the way with IIot adoption, other industries are becoming open to embracing IIot.

IOT Layers

Multiple perspectives can be taken when conceptualizing IoT layers.

From a technical standpoint, it comprises the

– Device layer (physical devices and controllers)

– Communication layer (connectivity protocols and data transmission)

– Application layer (data processing, analytics, and end-user applications).

From a functional point of view:

– Perception layer (sensing the environment),

– Network layer (data transfer and command dissemination),

– Application layer (delivering services to users).

Yet another lens to view IoT is from a user experience angle, distinguishing between

-Device interface

– Data analytics dashboard

– Actionable insights

Regardless of the viewpoint, separating IoT into distinct layers aids in better designing, understanding, and optimizing each segment for efficient and effective interconnected functionality.

The network layer, pivotal in digital connectivity, can be dissected into four distinct sections, each catering to specific needs and purposes.

1- Device Layer, where protocols like BACnet MS/TP operate, ensuring smooth communication between local devices such as sensors, actuators, and controllers.

2- Aggregation Layer comes into play, typically employing protocols like BACnet IP, which collate and standardize data from the device layer, bridging wider networks.

3- Gateway Layer is the intermediary, translating and routing data between the aggregation layer and broader networks, ensuring data integrity and appropriate translation between local and global protocols.

4- Internet Layer leverages expansive network technologies such as 4G, providing the highway for data to travel vast distances, interconnecting devices globally, and facilitating cloud-based storage and analytics.

MES Manufacturing Execution System

As far as I understand, there are three cores in MESsoftware

1- Work Order: Receive information from ERP. Work orders are formal documents, either paper or digital, that authorize and detail a specific task or job. This is often related to maintenance or service requests.

2- Scheduling: The process of planning and assigning specific work orders to resources (such as personnel, equipment, or time slots) to ensure that the tasks detailed in the work order are completed efficiently and on time.